Natural Gas Filling Stations

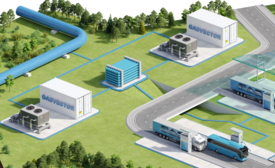

Our natural gas filling stations ar adapted to local conditions as well as to customer requirements. Our largest filling stations, which include a combination of several “GASVECTOR“ compressors, are able to refuel up to 600 busses per night. The smallest version “GASVECTORCITY“ is intended for simultaneous refueling of maximum two vehicles.

Our advantage lies in the flexibility to meet diverse demands!

The “GASVECTOR“ compressors including requested additional equippment can be installed in an industrial container or stationary inside a local building as needed.

Typical example of a "factory-made unit".

In a container (custom-made with noise and climate monitoring), all required components are usually integrated:

- Natural Gas Compressor - Capacity from 1000 up to 1 900 m³ / h

- Pressure storage

- Dryer (optional as required)

With a GASVECTOR variant, usually up to 6 fueling points can be operated (for example: 3 St natural gas dispensers with 2 hoses each).

The special feature of the GASVECTOR TWIN variant lies in its flexibility:

- Up to two compressors in one container

- Two containers coupled together and put together to form a system

- Typical applications for the GASVECTOR TWIN solution are larger capacity gas stoves: from 1,900 to 4,000 m3 / h or for applications with up to 10 natural gas pumps

FAS CNG Dispenser (Standard)

In the last couple of years, at FAS we designed and constructed many thousands dispenser ans filling stations. Those plants are being maintained and checked until today by us to guarantee our customers an error-free operaion.

Details

- EU-declaration of conformity and ATEX-label

- OIML R139 declaration of conformity (NMi) and PED-certification (SGS)

- Micro Motion CNG050 mass flow metre with measurement accuracy of 0,5%

- Temperature compensated tank pressure , 200 bar at a temperature of 15°C

- One filling hose

- Two pressure stages: low pressure and medium pressure

- Maxium flow rate: 77kg/min

- CETIL EAS2 processor with OIML R81, R117-1 and R139 certification (NMi)

- Communication with mass flow metre via Modbus

- Communication with payment terminal via EAS1 protocol

- Communication with SPS via Modbus for accessing dispenser data

- Graphic display with display of price per kg, dispensing per kg and lump sum price

- Storing of last 150 deliveries & 250 error codes

- Voltage: 230V AC, 50Hz, 300W

- Dispenser casing with EAS2 processor: IP54

- Base frame out of galvanised steel, primed and powder-coated

- Manual intake valve and filter for each pressure stage

- Automatic change of pressure stages with electric valves

- 1/2“ stainless steel piping

- On/Off or configurable key as deadman´s switch and delivery notice

- Emergency stop button

Inclusive

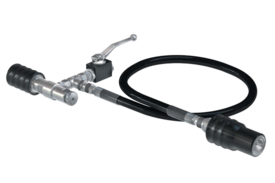

- VAR E30 CNG ST 3,5M filling hose – flexible filling hose 3/8“ and 1/4“ venting hose with breakaway coupling and NGV1 Stäubli filling pistol

FAS dispenser for CNG are produced and delivered for refueling of passenger cars, trucks or busses in several versions: Depending on the type of the dispenser, with either one or two hoses and with one up to three pressure stages.

Overview of available natural gas dispeners:

- CNG dispenser, type E30 CNG R 11 F

- CNG dispenser, type E30 CNG R 12 F

- CNG dispenser, type E30 CNG R 13 F

- CNG dispenser, type E30 CNG R 21

- CNG dispenser, type E30 CNG R 22

- CNG dispenser, type E30 CNG R 23

Supplies for Natural Gas Filling Stations

Ball valves for natural gas applications and high-pressure operation

Check valves for natural gas applications and high-pressure operation

Inline trailer breakaway for natural gas applications and high-pressure operation

CNG priority manifold for natural gas applications and high-pressure operation

Refuelling nozzles for natural gas applications and high-pressure operation